Everything You Need to Know About Servo Motors in Malaysia

If you’ve been working in the manufacturing industry with machines, you’ll be familiar with servo motors.

In this article, we will learn everything about servo motors in Malaysia and what kind of preventive measures you should take to get the best performance from these servo motors.

Let’s get started

What is a Servo Motor?

Servo motors or commonly known as servos are electronic devices that work as a rotary or linear actuator that focuses on precision in pushing parts of machines they are attached to. These motors are commonly used in angular or linear positions to have specific acceleration and velocity. It’s all about giving enough power to make specific machines work and generate the required performance.

A lot of manufacturing companies heavily invest in servo motors because it helps them to easily rotate and move objects precisely from specific angles and distances. Although many industries use servo motors, 90% of them are manufacturing companies because it makes the production work more efficient.

Types of Servo Motors

There are two main types of servo motors used widely in manufacturing industries which are:

- AC Servo Motor

- DC Servo Motor

AC Servo Motors

As many companies are using AC inverters, AC servo motors follow. Most manufacturing companies are using AC motors as they rely on encoders. These servo motors function with controllers that provide feedback with closed-loop control. As they can have full control of how the servo motors work with the highest accuracy, it has become the ideal choice for companies.

DC Servo Motors

DC servo motors are rarely used in companies today though it was used widely by top manufacturing companies a decade ago. As more and more electronic devices are compatible with AC, all the companies have completely switched to AC servo motors because they are advanced, reliable, easy to use, and cost-effective.

What types of electronic devices use servo motors?

It’s hard to tell which electronic devices are not using servo motors today. Most industries somehow will have servo motors whether on a small scale or large scale for their production activities.

For example, the automobile industries use servo motors in their car manufacturing itself. The car we drive today uses servo motors to control the speed and acceleration. When you step on the pedal of your car, it transmits the signal to the car’s computer system. The signal received by the servo motor attached to the throttle will adjust the speed depending on how you step on the pedal.

However, heavy-duty servos are used in manufacturing industries especially food manufacturing, pharmaceuticals, robotics and many more.

With industry revolution 4.0 on the rise in Malaysia, a lot of machinery and robots rely on servos to upkeep the performance and bring in profits for the companies.

The most common servo motor problems in Malaysia

In this section, our expert engineering team at STK Dynamic Engineering came up with a curated list of servo motor faults and errors.

Let’s check them out.

Electrical Issues

Although servo motors are mechanical, problems may arise with the electrical components that are connected to the engine. People often have the misconception that the motor is what having an issue, but the real issue certainly results from PLC, wiring or any small electrical element.

In certain scenarios, damaged cables can cause servo failure. When you have a short circuit, it can increase the voltage and destroy the motor.

Machine Overload

One of the most common issues encountered by servo motors is by overworking them. The harder you work with your servo motors the shorter their life span. You need to have regular maintenance for your servos to avoid premature failure.

Installation Issues

Improper installation is something people often overlook. Some installation of servos is done too fast which results in issues with belts and other electrical components. In some cases, improper installation techniques like using screws or items that are worn out and items that are not up to the standards.

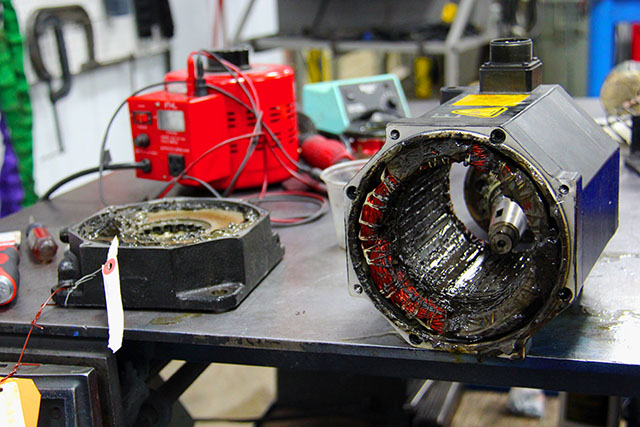

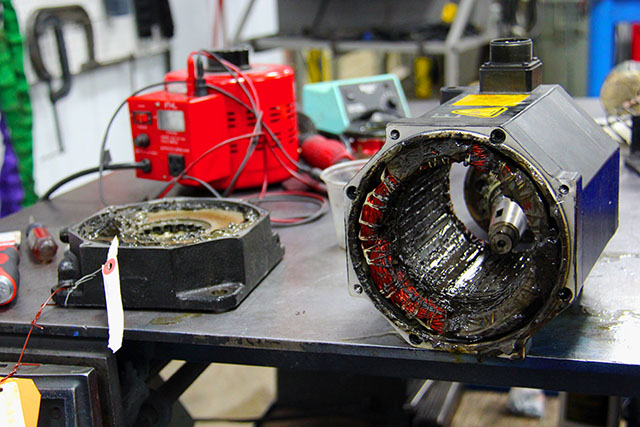

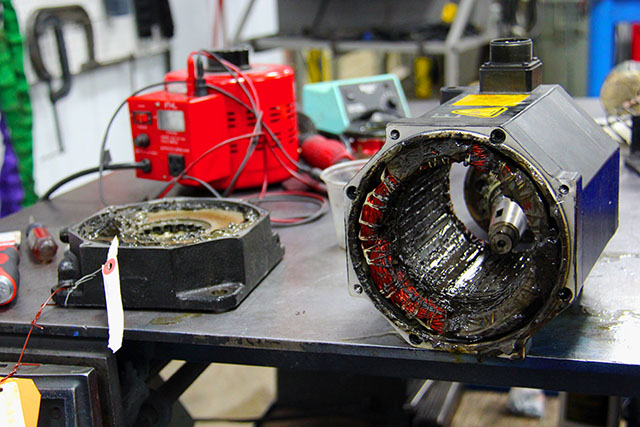

Contamination

Your entire machine can be affected when there is contamination from coolant, cutting fluid or even errant oil. Although it looks like a small issue, it can cause harm to servos as it will affect the bearings, encoder, the electrical system of the motor and also the windings.

Poor Power Supply

Having a poor power supply can be the cause of faulty servos. In some cases, fluctuation in the power supply can cause a spike of voltage that goes to the servo can cause damage and requires rewound.

Degrading of electrical components

When you’re using servo motors for a long, you will start seeing the electrical components like capacitors, diodes, and resistors start to get worn out. Even the feedback devices like encoders, resolvers and others start to lose their efficiency.

Many other things can cause damage and make servo motors faulty. And the best thing you can do is to get the right experts to troubleshoot the problems with your servos and get them repaired and maintained.

Why you should maintain your servo motors in Malaysia?

Maybe you’re wondering why not just keep using the old unit until it fails rather than having it repaired.

Does it make sense to pay for servo motor maintenance?

Let us enlighten you with the reasons why repairing and maintaining your servo motor makes the most sense.

Everything fails. Just a matter of time.

Did you know that mechanical and electrical components are designed to fail after a specific timeline?

With hours of workload applied to the components, it’s normal for them to break down at some point. However, some components tend to fail faster compared to others. With years of experience repairing and maintaining servo motors, we found that drive’s components are susceptible to ageing.

But the sad truth is that some components tend to damage the whole system and result in the complete failure of servo motors. Having huge damage and getting it repaired can be costly. To avoid such costly repair costs, it’s good to troubleshoot and replace critical components consistently.

Critical repairs can be avoided with scheduled maintenance

Our data from 20 years of repairing and maintaining servo motors shows all the components that can cause huge damage to servo drives. Before performing diagnosis and maintenance, we automatically change the critical components that have a shorter life span and have the potential to affect the entire servo drive.

Save your money with preventive maintenance

When it comes to repairing servo motors, it can be costly compared to maintenance because more time will be needed to repair them. On the other hand, you don’t want to overlook the productivity cost you’ll be losing when your servos start to malfunction. The worst-case scenario is when the failure occurs at the most critical time. That’s why preventive maintenance will be performed as per scheduled without disrupting the company’s production.

Identify weak electrolytic capacitors

When the electrolytic capacitors of servo motors start to age, it causes a lot of issues that reduce performance. Moreover, the leak of electrolytes on other components can cause physical damage. And that’s why it is important to replace the electrolytic capacitors of servo motors at some point rather than waiting for them to reach their destructive stage.

Our 20 years of experience have proven that preventive maintenance is the best solution for servo motors in Malaysia. And the maintenance needs to be conducted on your servos every 8-10 years. However, if you have servos operating in rough environments, we suggest performing frequent preventive maintenance.

Over the years we often get servo motors to be repaired which has been heavily contaminated with oil and chemical. It’s a critical task to clean them up without damaging the circuit board and other components.

If you’ve read the article from the start to the end, you should know everything about servo motors and why you should conduct frequent maintenance.